What I Have Learned About Propane Furnaces (The Hard Way)

or

The Mystery of the Flakey Furnace

Jed Margolin

This is about my experiences with a Ruud Model UGPH-07 EAUER gas furnace running on propane. It was manufactured in 1995.

Unless you have the knowledge and experience to safely work on this equipment (the voltage and the natural gas or propane) then you shouldn’t do it. You should have it done by a qualified professional. But even if you don’t do the work yourself the information may help you get your furnace fixed.

Index

B. I start to learn about gas furnaces.

C. The Ruud Control Board is replaced and the furnace works again. I examine the old board.

D. I make a schematic for the Ruud Control Board.

E. Now about the Control Board circuit, especially the Flame Sensor.

J. I invent a better flame sensing system

Details

A. My Ruud propane furnace stopped working. I didn’t want to learn all about gas furnaces, I just wanted to get it fixed by having someone else fix it. (It didn’t work out that way).

I live in the Virginia City Highlands, Nevada, which is in the mountains about 22 miles SE of Reno and five miles down the road from Virginia City. For pictures of my neighborhood click here.

It can get cold up here in Winter.

One morning in early December 2012 I woke up around 4 am to a cold house. Actually, it was just the upstairs that was cold. My house is two stories and I have two propane furnaces. One (100K BTUs) is in the garage for the first floor and the other (75K BTUs) is in the attic for the second floor.

Naturally, it was the furnace in the attic that wasn’t working. The blower was running but the air coming out of the vents was cold. The only way I could turn the blower off was to turn off the circuit breaker.

It was about 15 degrees Fahrenheit outside.

Although I am an engineer (electrical engineer) I didn’t want to try to fix the furnace myself. I just wanted to have an HVAC company come out and fix it and be done with it.

So, later in the morning I signed up for Angie’s List and called the HVAC company that was very highly rated. I will call them Company A.

Company A came out later in the day. Their Guy went into the attic, pulled the furnace panels and announced that the problem was that the limit switch had tripped. The limit switch is in the combustion compartment and opens if the temperature is too high.

I asked him what would cause the limit switch to trip. He said there were two main causes:

1. Dirty filters (Dirty filters reduce the airflow so the heat produced by the furnace isn’t being moved out fast enough);

2. A high wind had come through the attic (?). Presumably that would cause more propane to burn.

Neither explanation sounded right. My filters weren’t all that dirty and although there are times that we have 100 mph winds up here, that night wasn’t one of them.

The Guy reset the limit switch and cleaned the furnace, and the furnace worked again.

Note that when the limit switch opens, the control board shuts everything down except for the blower which it runs continuously.

B. I start to learn about gas furnaces.

1. Two days later, I again woke up in the early morning to a cold house. This time the symptoms were different. The furnace would come on and then immediately shut down.

Later in the morning I again called the Guy from Company A.

He wouldn’t come out. He said I should check the pressure switch. I don’t know why he wouldn’t come out again. I had paid him for the first service call and we didn’t have any snow on the roads (yet). Maybe he had a thing about attics.

That meant I had to do exactly what I didn’t want to do: get involved in fixing it myself.

I went into the attic, opened the furnace panels, and found the pressure switch. I disconnected the wires to the switch and connected an Ohmmeter to the contacts. When I sucked on the tube the contacts closed but there was a burbling sound. This was my first experience with a furnace pressure switch but I was pretty sure that it wasn’t supposed to burble.

By then I had discovered that the major distributor of HVAC and plumbing parts in Northern Nevada is Western Nevada Supply (http://www.goblueteam.com/). That’s where the HVAC service companies get their parts. Western Nevada Supply stocks just about everything you would need to install and fix HVAC systems. You can usually get equipment and parts cheaper online but then you have to wait for it to be delivered and people usually want their HVAC system fixed now.

I got a pressure switch for my furnace and, just for grins, a new flame rod and installed them. (I had already started learning about gas furnaces.)

2. A few days later, I again woke up in the early morning to a cold house. Same symptoms as the last time. The furnace would come on and then shut down.

This time I went to the Yellow Pages and picked out a company with a good ad, Cavallero Heating and Air Conditioning in Carson City (http://cavalleroheatingandair.com/) My mountain community is about as close to Carson City as it is to Reno.

Mike from Cavallero came out that day.

He verified that the new Pressure Switch and Flame Rod were good.

He noted that the Flame Good LED took an unusually long time to come on.

He separated the wire to the Flame Sensor from the bundle of wires it was in but it did not help. (Sometimes it does.)

He replaced the Igniter.

We decided that the only thing left was the Control Board.

He said I could probably buy one cheaper than he would have to charge me if he bought it. (He probably would have bought it from Western Nevada Supply, too.)

As he was getting ready to leave, it started to snow.

3. The next day I bought a new (and genuine Ruud) Control Board from Western Nevada Supply Company. By then it was snowing even in Reno. (My house is at an altitude of about 6,000 feet. It snows here first, and sometimes it snows here but not in Reno.)

Due to the snow, the roads in the Highlands became icy and weren’t safe without a vehicle that could handle an icy hill. I didn’t want Cavallero to risk the roads. And I didn’t want to replace the Control Board myself. (Ok, I was spooked by my furnace.)

Besides, by then I had discovered that the furnace would work ok until the outside temperature dropped below 20 degrees. At that point the attic temperature would be in the high 30s.

I wondered if the Control Board was too cold so I tried running the blower to warm the Control Board with air from the house. No joy. As it turned out, if I had run the blower longer it might have worked.

While I was waiting for the roads to clear I called my propane company (Bi-State) and they came out and checked the propane pressure at the furnace with both furnaces running. Bi-State can get through no matter how bad the roads are.

The propane pressure was good.

And I did something else.

The Control Board has three LEDs on it.

1. Power: We have Power.

2. Flame Good: The Flame Sensor says we have a good flame.

3. Diagnostic Code: If there is a problem it flashes a code. The number of flashes indicates the problem.

Newer furnaces have a window in the cabinet panel so you can see the LEDs without taking the panel off.

Mine didn’t have one so I cut a hole in the panel and put a square of clear acrylic sheet over it. The control board is in a plastic box with a metal cover so I also cut a hole in the metal cover and covered it with acrylic.

That way I could see the LEDs without removing the panel. And since the furnace is in the attic I pointed a wireless surveillance camera at the LEDs so I could see them without going into the attic.

C. The Ruud Control Board is replaced and the furnace works again. I examine the old board.

1 After ten days of moderate winter temperatures (for the Highlands) the forecast called for nighttime temps in the teens.

I called Cavallero and they agreed to come out even though the roads were still icy.

Chris came out and installed the new board. When he fired up the furnace the Flame Good LED came on immediately with the flame with no delay.

This turned out to be an important clue because, with the old control board, the Flame Good LED took an unusually long time to come on. It could take as long as 20 seconds.

2. Since I was already involved and had spent a fair amount of money on it I wanted to understand the problem in case it happened again. I started with a physical examination of the control board.

a. The old control board (62-24084-01) has been superseded by a new board (62-24084-82). However, they are both made the same way. I suspect that the difference is a software update in the microcontroller, a PIC16C57 by Microchip (http://www.microchip.com/wwwproducts/Devices.aspx?product=PIC16C57). For the datasheet click here.

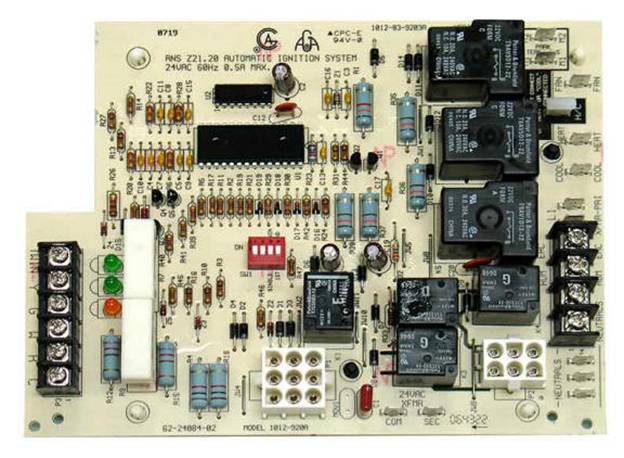

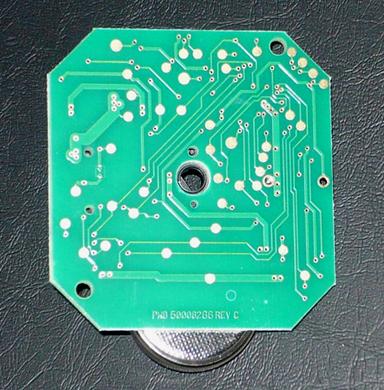

b. The control board is a single-sided Printed Circuit Board (PCB).

The following pictures are from:

This is what a single-sided PCB looks like.

The copper (and therefore the traces) are on only one side of the board.

Figure 1

![[​IMG]](index_files/image001.jpg)

Here is a double-sided (double Layer) PCB. The traces are on both sides of the board.

Figure 2

![[​IMG]](index_files/image002.jpg)

The advantages of the double-sided PCB include:

a. You have more room and flexibility to run traces. In a single-sided PCB you are much more likely to have to use wire jumpers on top of the board in order to complete some of the circuits.

Since you have more room you have a better chance of being able to have good Grounds. When Grounds use thin traces you have more electrical noise. Wide traces (and large copper areas) make for less noise in the Grounds.

b. All of the holes are plated through, even the ones that do not have traces on both sides of the board.

When you solder a wire in a plated through hole the solder wicks into it, filling the hole as shown above.

This provides a stronger mechanical connection for the part. Here is why you want a strong mechanical connection for the parts.

a. If the board is subject to mechanical vibration the parts will vibrate and put mechanical stress on the soldered joints. It might break soldered joints. Note that the control board is mounted in the blower compartment where it is subject to vibration whenever the blower is on.

b. If the board has a connector and you unplug the connector you may be putting a large amount of force on the soldered joints. For this reason, when you are unplugging a connector you should try to hold on to the connector body on the board to reduce the force on the soldered joints.

The Ruud control board has two connectors, the larger one having nine pins. (You can also see several wire jumpers on top of the board.)

Figure 3

Ruud’s use of a single-sided PCB explains why the connectors have a reputation for damaging the PCB joints when you unplug the connector.

This is the bottom of the board.

Figure 4

There are some generous ground areas but they are only for high-current mains traces. The grounds for the PIC16C57 microcontroller and associated circuitry are wimpy.

Note that there are a few slots in the board. They are there to provide positive isolation between mains power and the lower voltage circuits.

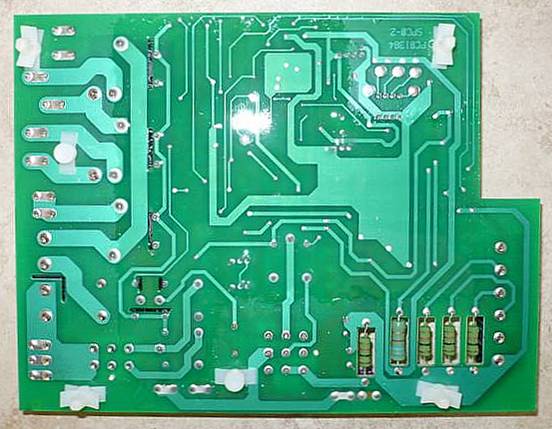

Since I have another Ruud furnace downstairs that was also made in 1995 I decided to be proactive and get another control board for it. I found one online really cheap and bought it. I thought I was buying another Ruud board but it turned out to be a replacement board (ICM288) made by someone else. It was made by ICM Controls (http://www.icmcontrols.com/) It turned out to be a lucky mistake.

The ICM288 is pretty much fit and function compatible with the Ruud 62-24084-82. (The diagnostic LEDs are not exactly in the same place so they might not be visible through a window.)

The ICM288 is a really nice board.

a. It is a two-layer board with good ground coverage.

b. It uses many surface mount devices (SMDs) so most of it can be stuffed and soldered by machine. This method of manufacturing helps keep the cost down. The large parts would still have to be stuffed by hand. They would probably be stuffed and soldered separately after the SMDs were soldered. Notice that in the lower left there are some resistors mounted in cutouts in the board. This provides better airflow to cool the resistors.

Figure 5

Figure 6

For the documentation on the ICM288 board click here.

D. I make a schematic for the Ruud Control Board

I wanted to know how the control board is supposed to work so I followed every trace to every pin on the old Ruud board and made my own schematic.

For my schematic click here. (The wiring diagram for the furnace is from the Ruud manual.)

Before I discuss the circuit design, for the Ruud GHP Series Installation manual click here.

It contains useful information about how the furnace is supposed to work.

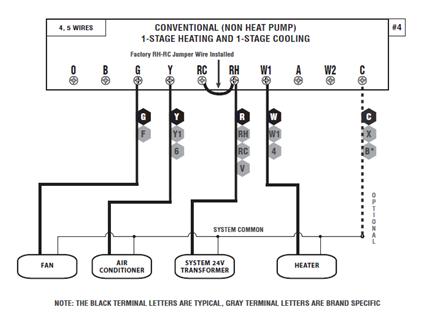

From PDF pages 24-25:

This is for the unit with the Hot Surface Ignition as opposed to the Spark Ignition.

1. Each time the thermostat contacts close, the induced draft blower (inducer) begins a prepurge cycle.

2. The air proving negative pressure switch(es) closes.

3. Five seconds after the pressure switch(es) close, the hot surface igniter begins heating for 30 seconds to full temperature. The induced draft blower operates for the complete heating cycle.

4. After the 30-second igniter warm up, the gas valve opens for an eight second trial for ignition.

5. The igniter lights the gas burners and stays energized for the first eight seconds after the gas valve opens.

6. Seven seconds after the gas valve opens the remote flame sensor must prove flame ignition for one second using the process of flame rectification. If the burners don't light, the system goes through another ignition sequence. It does this up to four times.

7. The main blower starts 20 seconds after the burners ignite.

8. When the thermostat cycle ends, the gas valve closes, the burners go out, the induced draft blower runs for a five second post-purge, and the negative pressure switch(es) open.

9. The main blower continues until timed off by the setting on the integrated furnace control board.

10. [My comment: If, at any time after ignition the flame sensor indicates No Flame, the gas valve is turned off and the furnace shuts down after running the Blower for awhile.]

This is the sequence if the system doesn't light or doesn't sense flame:

1. On a call for heat, the control runs the inducer for 30 seconds to prepurge.

2. Five seconds into prepurge, the hot surface igniter begins heating for 30 seconds. The inducer continues to run.

3. After the 30-second igniter warm up, the gas valve opens for an eight second trial for ignition. The inducer continues and the igniter stays energized.

4. If flame is not sensed during the eighth second after the gas valve opens, the gas valve closes, and the igniter de-energizes.

5. After five seconds of inter-purge, the igniter heats for 30 seconds. After 30 seconds, the gas valve opens for nine seconds. If no flame is sensed, it closes the gas valve, the igniter de-energizes, Both the main blower and the inducer operate for 180 seconds before the next ignition trial.

6. It repeats this process up to four times. At the end of the last try, the inducer stops immediately. The system is in "soft" lock out for one hour.

7. The above sequence will repeat after a one hour delay. It will continue repeating until ignition is successful or the call for heat is terminated.

8. To reset the lock out, make and break power either at the thermostat or at the unit disconnect switch for 5 to 10 seconds. It then goes through another set of trials for ignition.

There is also the Limit Switch (PDF page 29):

SAFETY FEATURES

LIMIT CONTROL

The high limit cut-off temperature is set at the factory and cannot be adjusted. The temperature setting prevents the air temperature leaving the furnace from exceeding the maximum outlet air temperature, which, if exceeded, will shut the furnace down. Some reasons which could cause the outlet temperature to exceed the range include: failed indoor blower, dirty filters, etc.

OVER TEMPERATURE SAFETY SWITCHES

Furnaces are equipped with safety switches to protect against overtemperature conditions in the burner compartment, which, if tripped, will terminate the heating cycle. In the event of an overtemperature condition, the switch will shut the furnace down. The switch for the dedicated UPFLOW FURNACE and DOWNFLOW is located just above the burners on the blower divider panel. Switches for the UPFLOW/ HORIZONTAL FURNACES are located on either side of the burner brackets and just above the burners on the blower divider panel. If a switch is tripped, it must be manually reset. DO NOT jumper or reset this switch. If this switch should trip, a qualified installer, service agency or the gas supplier should be called to diagnose and/or correct the source of tripping. If this unit is mounted in a closet, the door must be closed when making this check.

It doesn’t mention that when the limit switch trips it runs the blower continuously until you do a power-reset of the furnace.

I mentioned that one of the LEDs on the Control Board is a Diagnostic LED. If there is a problem it is supposed to blink a code as follows (from PDF page 34):

|

One Blink followed by a 2 second pause |

One Hour Lockout |

|

|

|

|

Two Blinks followed by a 2 second pause |

Pressure Switch is open |

|

|

|

|

Three Blinks followed by a 2 second pause |

Limit Switch is open |

|

|

|

|

Four Blinks followed by a 2 second pause |

Pressure Switch is closed |

The ICM Control Board has additional fault codes. And, as it turned out, the Diagnostic LED on my old Ruud Control Board never blinks a code no matter what the fault is except for a Twinning error. Then it flashes continuously.

E. Now about the Control Board circuit, especially, the Flame Sensor.

It is very important to be able to detect that a flame is actually being produced when the gas valve is on. Otherwise the unburned fuel will continue to flow and build up. It may cause asphyxiation, and if it finds an ignition source it may explode. Boom! There goes your house. And maybe you, too.

1. There are two main methods used to detect flames.

a. One method uses an optical detector to look at the ultraviolet light produced by the flame. Flames produce a broad spectrum of energy from infrared to ultraviolet. Although sensors for infrared or visible light are much cheaper than ultraviolet sensors, an infrared or visible light sensor could be fooled because the walls of combustion chambers tend to radiate visible and infrared energy for a period of time after the flame is lost. On the downside, Ultraviolet Flame Detectors are very expensive.

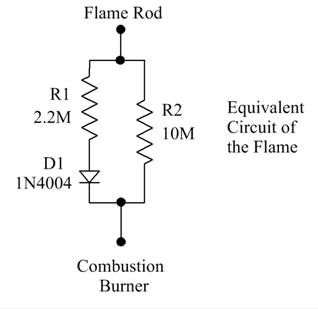

b. The other method uses the electrical properties of a flame by placing a metal rod in the flame (or where the flame is supposed to be). The flame rod is just a metal rod in a ceramic insulator that allows it to be mounted to the cabinet without shorting out the rod. Flame Rods are cheap. (Guess which one is in your home furnace.)

Figure 7

If you have never seen a combustion burner this is what one looks like.

Figure 8

A combustion burner is a tube with a hole that allows the air to mix with the gas before it is burned. For that reason it is called a premixed flame. (The flow of the gas sucks in the air. If the tube is vertical then the heat differential can also help suck in the air.) There are flames that are not premixed, they are called diffused flames. A candle has a diffused flame because the air diffuses into the gas (the wax vapor/gas) at the flame. A diffused flame is less efficient than a premixed flame.

Note that in the above picture the ends of the gas tubes are shaped somewhat like a rocket engine. The ones in my furnace are straight.

Also note that there are three flame tubes. The flames are aimed at a heat exchanger to heat the air circulating through your house. (You don’t want to have the products of combustion in your house.) A single large flame would create a single large hot spot. Using multiple flame tubes distributes the heat more evenly along the heat exchanger. It also allows the furnace manufacturer to make several models of a furnace that differ only by the number of flame tubes and therefore its BTU heating rating. The furnace in my attic is 75K BTUs and has three combustion tubes. The furnace in my garage is 100K BTUs and has four combustion tubes.

Now we have a flame rod and a combustion burner. The return current path for the flame is through the combustion burner which is attached to the cabinet, which by definition is ground. For safety, all exposed metal parts of an appliance must be grounded. Also for safety, the gas line connected to the combustion burner must be grounded.

Now here’s the thing.

The electrical characteristics of a flame cause current to be conducted preferentially in one direction over the other. This is commonly called “flame rectification” and the flame is called a “flame rectifier” or “flame diode”. That gives the flame too much credit. It is not a very good diode. Here is an equivalent electrical circuit with representative values.

Figure 9

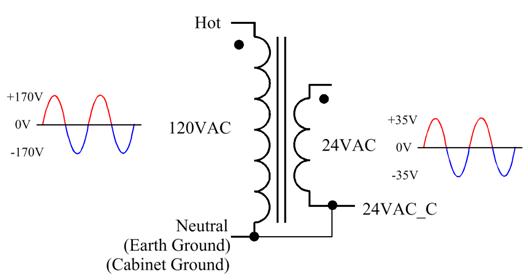

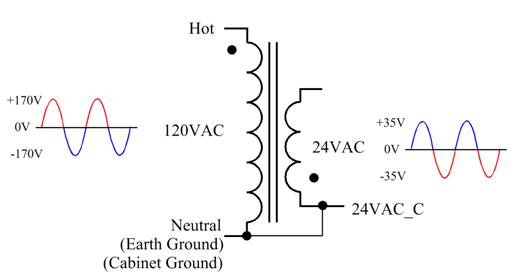

Because the flame is not a very good diode, the way it is used requires a substantial voltage to produce a usable effect. In my furnace Ruud uses the raw 120VAC Mains. (That seems to be standard in most consumer furnaces because it is the cheapest way to do it.)

Figure 10

I have a problem with this.

Because the combustion burner is Ground, it means that the Mains Neutral must also be connected to Ground.

According to the National Electrical Code this may only be done (and is required to be done) at the service entrance to the building and no place else. As a result, an electrical connection problem outside the furnace at the service entrance may cause a flame sensing circuit to malfunction even though there is no problem in the furnace itself.

How could this happen?

Maybe you have an old house and the Mains Neutral was never connected to Ground.

How could your furnace ever work like this?

The current through the flame circuit is on the order of several tens of microamps. The National Electrical Code allows a leakage current between Ground and Neutral of 4 milliamps to 6 milliamps. Above that, a Ground Fault Interrupter is required to trip. That is so you won’t get electrocuted in your bathroom by a faulty blow dryer.

Four milliamps is 100 times greater than, for example, 40 microamps.

You could have an appliance such as a washing machine that has a ground leakage current of 4 milliamps. Your flame sensor circuit will work. Then you get a new washing machine with no detectable leakage and your furnace will stop working.

If you replace the washing machine at the beginning of the Summer and don’t use your furnace until several months later you might miss the amazing coincidence.

Here is another thing that could happen.

Suppose the Mains Neutral and Ground wires at your service entrance (outside the house) are of a mixed type. One is Copper and the other is Aluminum and the terminal block where they are connected is not rated to handle the mix of Aluminum and Copper.

Now you have a really cold night and the terminal block connector cannot handle the different thermal expansion rates of Aluminum and Copper. One expands too much (or too little) and is no longer connected. Your flame sensor (and furnace) will fail to work just when you need it the most.

And later that day when you have Furnace Repair Guy come over the temperature has come up (it’s daytime) and now the furnace works. Bummer.

My other objection to having the furnace send the flame current through the Ground wire is that it is sending a signal through the Ground Wire. I think Ground should be used only for Ground.

2. Since we will be testing the flame sensor there is an important matter to consider.

The circuit ground in the circuit that measures the voltage produced by the flame sensor is not the same as the 24VAC Common/Cabinet/Combustion Burner/Mains Ground/Neutral.

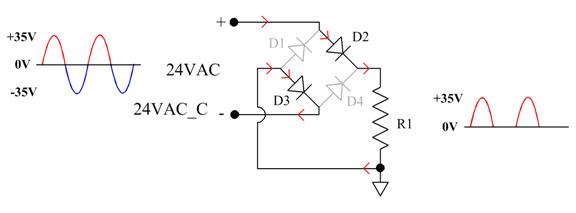

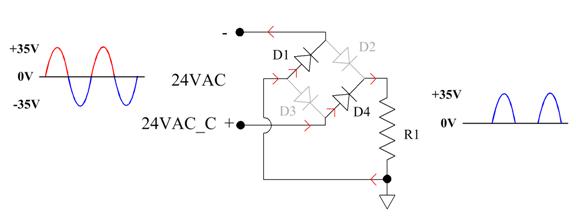

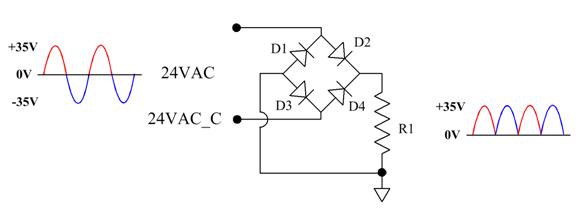

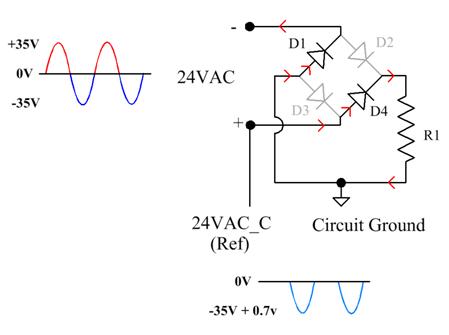

From the Schematic Page 3 note that the 24VAC goes to a bridge rectifier but the output is not filtered, so all the relays operate on pulsating DC. When you rectify 24VAC you get a pulsating +35V.

Figure 11

That’s not the problem. It’s just strange.

The +35PV gets zenered down and filtered for the +5V (VDD) for the microcontroller. Notice that D5 is needed because the +35PV is not filtered.

Figure 12

That’s not the problem either.

The problem is that the 24VAC Common/Cabinet Ground/Mains Neutral/Mains Ground is not the same as the Circuit Ground used by the microcontroller.

Figure 13 (From Figure 11)

Note that the symbol for Circuit Ground is:

![]()

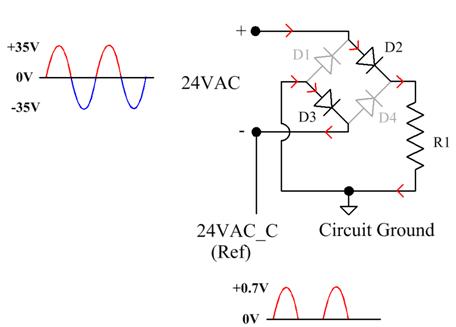

This is what happens.

During the positive half-cycle of the 24VAC the current goes through Diode D2, Load R1, and Diode D3. (The waveform is across Load R1.)

Figure 14

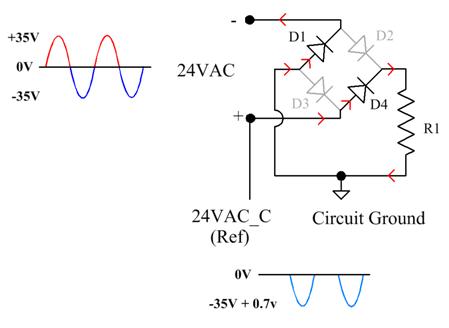

During the negative half-cycle of the 24VAC the current goes through Diode D4, Load R1, and Diode D1.

Figure 15

The result is full-wave rectification of the 24VAC. That is how a bridge rectifier works.

Figure 16

The problem is that there is a diode between Circuit Ground and 24VAC_Common (Cabinet Ground/Mains Neutral/Mains Ground).

On the positive half-cycle Diode D3 is on so there is only a diode drop (about 0.7V) between 24VAC_Common (etc.) and Circuit Ground.

Figure 17

However, on the negative half-cycle Diode D3 is off and there is almost -35PV between 24VAC_Common (etc.) and Circuit Ground.

Because of this whenever the microcontroller (referenced to Circuit Ground) must read a signal referenced to 24VAC_Common the signal must be shifted and limited. (All of the signals from the thermostat are referenced to 24VAC_Common.) This is how it is done:

Figure 19

The relays are run from the +35PV whose return is Circuit Ground so no level

shifting is necessary. Integrated Circuit U2 contains transistors with

uncommitted open collectors and a common emitter connection which is grounded

to Circuit Ground.

Figure 20

The relay circuit for the Gas Valve has something extra.

Figure 21

The control must be continuously toggled in order to keep the relay energized. If it sticks either high or low the relay will open. You really don’t want the Gas Valve open unless you really want the Gas Valve open. The Inducer Blower relay has the same circuit. (If the Inducer Blower turns off, the Pressure Switch will open and the furnace will shut down.)

F. I make a Test Fixture

Important Note:

Because Circuit Ground and 24VAC_Common have a substantial voltage between them you have to careful when you measure voltages and waveforms on the board.

1. 24VAC_Common is connected to 120VAC Mains Neutral.

2. If you use an oscilloscope, the oscilloscope ground will already be connected to Mains Ground through the three-prong power cord. If you connect a probe ground to Circuit Ground you will send current through the probe ground and probably burn it out. Or burn something else out. (Do Not float the oscilloscope.)

3. If you use a two-channel oscilloscope and connect one of the probe grounds to Circuit Ground and the other probe ground to 24VAC_Common you will obviously have the same problem. You will still have the problem if you float the oscilloscope (Do Not float the oscilloscope) or put the oscilloscope on an isolation transformer.

To avoid this I made a Test Fixture with switches to simulate the various furnace systems and LEDs to show the actions performed by the Control Board. Since the 120VAC Mains just goes through relay contacts to provide power to the Inducer Blower, Igniter, and Main Blower (and those are represented by LEDs) I used a safe 12VDC instead.

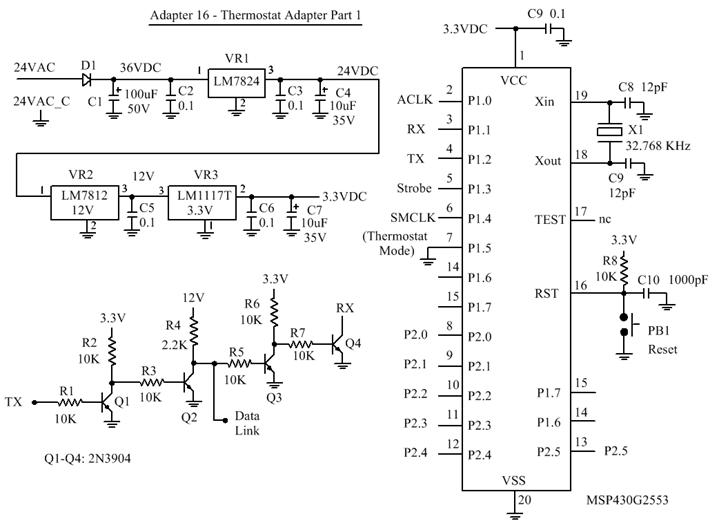

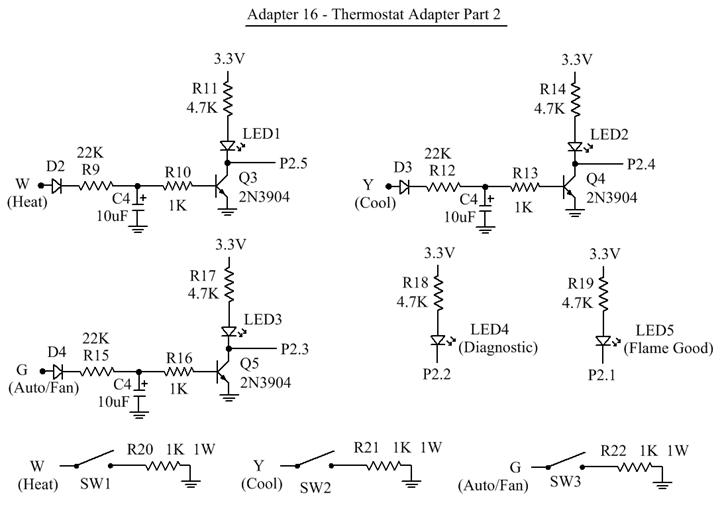

For the schematic of this Test Fixture click here.

1. Note that the 24VAC transformer has to be connected to the 120VAC Mains with its own plug since the Neutral and Hot blades on the Control Board will have 12VDC on them.

2. Also note that since I do not have 120VAC on the Control Board I spoof the Flame Circuit with a 9V battery. The circuit has to be connected to the proper places on the Board. I made the voltage adjustable in order to investigate the operation of the Flame Circuit.

Figure 22

The voltage produced by the Flame Sensor circuit is either 0 Volts (no flame) or negative (a flame). Q1 is an N Channel JFET (Junction Field Effect Transistor). At zero gate voltage JFET Q1 is On and RC6 is Low. A sufficiently negative gate voltage turns Q1 off which makes RC6 High. The negative voltage produced by the Flame Sensor is used to charge capacitor C17.

Q2 is a P Channel JFET. A P Channel JFET is the Bizarro World version of the N Channel JFET. Everything is opposite. Instead of controlling a positive voltage between the Drain and the Source, a negative voltage is controlled. Instead of a negative gate voltage turning it off, a positive gate voltage turns it off. This allows a positive voltage produced by the microcontroller (RC7) to turn Q2 on, which discharges Capacitor C17.

The microcontroller does not have enough I/Os for everything so they are cleverly multi-purposed. When RC7 is Low, Q2 is On which discharges Capacitor C17. When RC7 is Low it also grounds one side of DIP Switches 1-4. This allows DIP1 to be read by RC5, DIP2 to be read by RC4, DIP3 to be read by RC3, and DIP4 to be read by RC2.

When RC7 is High, Q2 is Off which allows Capacitor C17 to be charged by the Flame Voltage. It also stops grounding the DIP Switches which allows RC5, RC4, RC3, and RC2 to do other things. RC5 becomes an output to control the Flame Good LED, RC4 becomes an output to control the Diagnostic LED, RC3 becomes an output to control Twinning, and RC2 remains an input but monitors the Limit Switch.

The Flame Sensing Circuit in Action

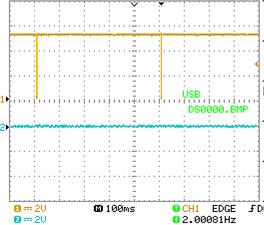

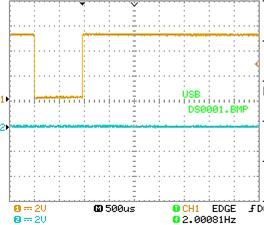

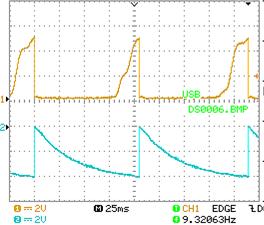

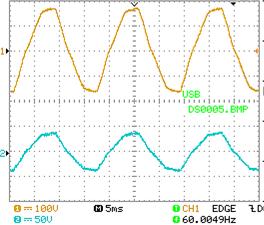

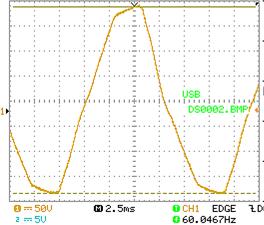

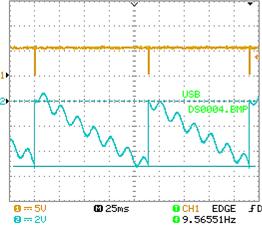

In the following figures the top trace is RC7 and the bottom trace is the Flame Voltage at C17. RC7 is normally high so Q2 is off. When there is no flame the voltage at C17 is 0V. Q1 is On and RC6 is Low.

However, RC7 pulses Low every 500 ms (1/2 second) to check the DIP Switches. It also discharges C17 in case it is holding a small charge.

Figure 23

The pulse width is 1,000 us (1 ms):

Figure 24

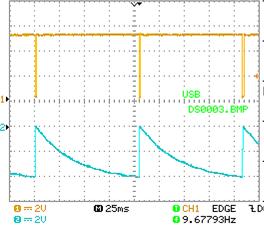

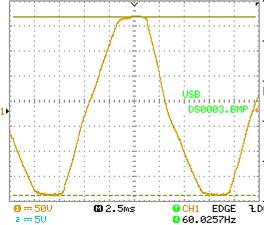

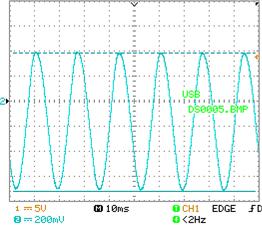

When the Flame Voltage is negative enough to turn Q1 off, RC6 goes high and the RC7 pulse happens more frequently. The rate of the RC7 pulse depends on how long it takes the Flame Voltage to reach about -4V. When it is about -4V the time is about 105 ms.

Figure 25

When the Flame Voltage is more negative, then the RC7 pulse ends sooner. Here it is at about -6V. The time is about 43 ms.

Figure 26

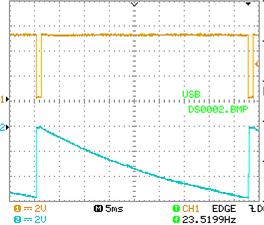

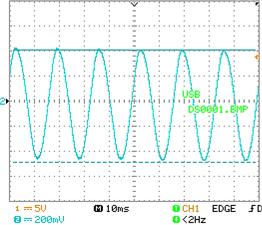

In the following figures the top trace is RC6 and the bottom trace is the Flame Voltage at C17.

With a healthy Flame Voltage of -6V the RC6 pulse width is about 19 ms.

Figure 27

But with a Flame Voltage of only -4V the RC7 pulse is right at the edge of usability.

Figure 28

The voltage at which an N Channel JFET begins to turn off is called the Threshold Voltage (or the Gate-Source Cutoff Voltage). The Threshold Voltage is different for different type numbers of JFETs.

The number on Q1 is “N512” but I haven’t found a datasheet for it. A representative N Channel JFET is the Fairchild J111. According to the datasheet (click here) the Threshold Voltage for the J111 is about -3V. (PDF Page 2) For other members of the series it is -1V (J112) and -0.5V (J113).

The Threshold Voltage of a JFET changes with temperature in a complicated manner. I used Freeze Spray on Q1 but it did not change the RC7 period by much. Importantly, the Flame Detect did not stop working. Since Freeze Spray says it cools components down to -65 degrees Celsius (-85 degrees Fahrenheit) it is clear that my cold attic did not affect the Q1 threshold voltage.

I thought I was on to something when I measured R32, which is supposed to be 22M. It measured 36M. I didn’t have any 22M resistors so I put together a replacement with two 10M resistors and a 1M resistor. (One of the 10M resistors was high.) Separately they measured within tolerance but together they measured 32M. What?

I was using an old Wavetek DM27XT and measuring above 20M meant switching to a higher scale. I changed to a very old Micronta (Radio Shack) DVM and the 22M measured 26M. The combo of 10Ms and 1M measured properly as 21.6M. I confirmed it with a Greenlee DM-300. I thought that my Wavetek DM27XT was an accurate meter but I guess it isn’t, at least for high resistances.

The difference in R32 between 22M and 26M would not explain the failure of the Ruud board to recognize the flame in a timely manner in my cold attic.

I used the Freeze Spray on the original R32. It went from 26.66M to 30.51M for an increase of 14%. When I used the Freeze Spray on one of the 10M resistors it went from 10.80M to 11.02M for an increase of 2%. Since both are carbon film resistors something is not right with the 22M resistor. Still, it also doesn’t explain the failure of the Ruud board to recognize the flame in a timely manner in my cold attic.

The microcontroller (PIC 16C57) clock uses a resistor (R23) and capacitor (C13) to set the frequency. It’s a really cheap way of doing a clock. It drifts with temperature as the resistor and capacitor drift with temperature. (The ICM288 uses either a crystal or a resonator.) I measured the clock output at pin 26 (which is 1/4 the internal clock) at 503 KHz. Using Freeze Spray on R23 and C13 changed it to about 480 KHz, a decrease of almost 5%. That wouldn’t explain the problem either, especially considering how cold the Freeze Spray is.

Before we leave the Flame Sensing circuit I will note that the Flame Sensing Circuit works all the time regardless of the state of the furnace.

The microcontroller is smart enough to know that if the Flame Sensing Circuit says there is a flame when there shouldn’t be one (like if the Gas Valve is closed) it goes into Safe Mode and will turn on the Inducer Blower and the Main Blower. It also flashes the Flame Good LED rapidly and continuously.

The Flame Sensor Circuit could indicate a flame if the furnace has been on but, when it was instructed to turn off, the Gas Valve has stuck open. In that case the best thing to do is to assume there really is a flame.

Of course, if there really is a flame and it cannot be turned off, your house is going to get very warm.

Even worse is if the Gas Valve gets stuck open without a flame. This could happen if the Igniter is broken, the furnace tries to start, doesn’t get a flame, and then the Gas Valve sticks open.

If this happens, hopefully you will smell the gas in time to get out. (Get Out, don’t investigate, don’t turn on any lights, just Get Out.)

I suspect that gas furnace explosions do not happen very often.

Most of the discussions on the Cortex about gas appliances exploding are about water heaters. In particular, if there is a flood the springs in the Gas Valve can become corroded.

However, since many gas furnaces are located next to gas hot water heaters, if there is a flood it could affect the gas valves in both units. (If you have a flood that bad you will have more problems than just your furnace.)

H. I investigate the possibility that the phase of the 24VAC transformer makes a difference in how well the Flame Circuit works.

Transformers have a phase. They can either maintain the phase between the primary and and secondary windings or they can invert it. Frequently transformers are marked with a dot to indicate phase.

This one is in phase.

Figure 29

This one is out of phase.

Figure 30

The primary is connected to the 120VAC Mains which is used by the Flame Sensor.

The secondary gets rectified but the 24VAC_Common is not the same as the Circuit Ground which provides the reference for reading the Flame Voltage.

During half of the wave it can be different by as much as 35V. This is a reproduction of Figure 18.

Figure 31

In order to investigate I needed to operate the Control Board at 120VAC, so I reworked my test fixture. Click here.

Note that for safety I ran it from an isolation transformer. Also note that:

a. A Variac is not an isolation transformer.

b. You can make a simple isolation transformer from two transformers connected back-to-back. I used two 24VAC 3A transformers. Click here. This method loses efficiency so the voltage you get out will be a few volts lower than what you put in. It is for the test fixture only. It won’t power a furnace.

c. If you want a real isolation transformer the Triad N-68X looks good. They say that “the primary and secondary windings are precision wound on separate arbors, then assembled on a laminate core side by side separated by insulation.” If the primary and secondary windings are wound concentrically you could have a short between them. Concentric windings also have capacitive coupling between them. As of this writing Allied Electronics is selling the N-68X for $13.13 . http://www.alliedelec.com/triad-magnetics-n-68x/70218526/?mkwid=sabYU23qn&pcrid=30980760979&gclid=CPP8soaFhskCFYZlfgodM4UFAw#tab=specs

I also made a Flame Spoofer to simulate the electrical characteristics of the flame. I put it on a switch for reasons that will become apparent soon.

Here is the theory.

The voltage that is used for the Flame Sensor comes from the 120VAC Mains whose ground reference is 120VAC Neutral (24VAC_Common) but the reference used to measure the Flame Voltage comes from Circuit Ground which is different from 120VAC Neutral. (See Figure 17 and Figure 18 for why this happens.)

In one half-wave the voltage between 24VAC_Common and Circuit Ground will be almost 0V and in the other half-wave it will be almost 35V.

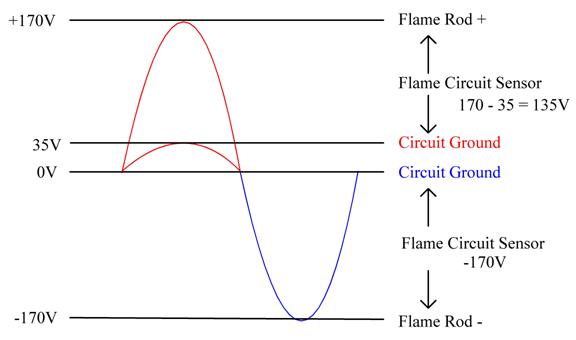

In the following figures remember that the flame conducts current preferentially in one direction, the positive direction. This property is used to shunt the positive voltage to ground (somewhat) but not the negative voltage. This gives a net result of a negative voltage to be detected. (The Red Circuit Ground is the Circuit Ground during the positive half-cycle, the Blue Circuit Ground is the Circuit Ground during the negative half-cycle.)

When the 24VAC transformer is phased one way it will be:

Figure 32

This reduces the positive voltage but not the effective negative voltage. That should be considered good.

When the 24VAC transformer is phased the other way it will be:

Figure 33

This reduces the effective negative voltage but not the effective positive voltage. Not good.

How does this work in real life?

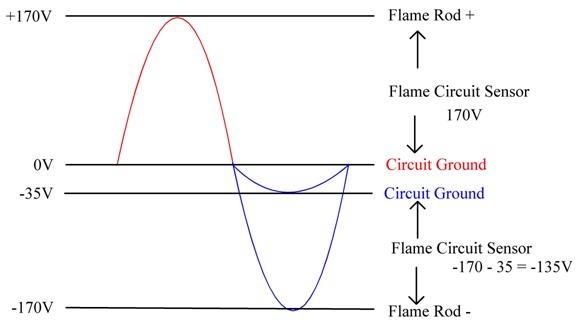

1. Referring to Figure 22, C20 provides AC coupling to the half-wave waveform in Figure 18.

The average voltage of a half-wave rectified waveform is Vpeak/pi.

Figure 34 (from Figure 18)

After C20:

Figure 35

As a result of the filtering done by C17 and the various resistances in the circuit we get an asymmetrical sine-like wave. (See Figure 45 later on.)

I have done a bunch of tests on my board to show the effect of having the Flame Sensor referenced to 120VAC Mains/24VAC_Common while the circuit used to measure the flame voltage uses the Circuit Ground as a reference. Then I reversed the phase of the 24VAC transformer to see what effect it has.

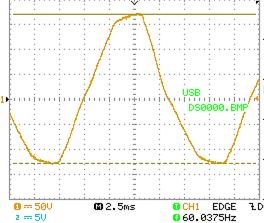

120VAC and 24VAC - In Phase

Figure 36

This is before C20: Max = +170V, Min = -128V

Figure 37

This is after C20: Max = +152V, Min = -134V

Figure 38

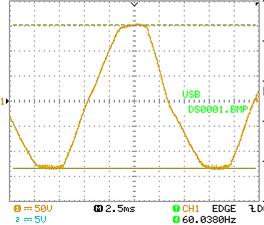

120VAC and 24VAC - Out of Phase

Figure 39

This is before C20 (I moved the 0V point so it would fit on the screen without reducing the scale):

Max = +208V, Min = -164V, Sum = 44V

Figure 40

This is after C210: Max = +188V, Min = -168V

Figure 41

Summary

|

120VAC in phase |

Max (V) |

Min (V) |

Sum (V) |

|

Before C20 |

+170 |

-128 |

+42 |

|

After C20 |

+152 |

-134 |

+18 |

|

120VAC out of phase |

Max (V) |

Min (V) |

Sum (V) |

|

Before C20 |

+208 |

-164 |

+44 |

|

After C20 |

+188 |

-168 |

+20 |

Therefore:

1. When the 24VAC transformer is in phase with the 120VAC, the voltage after C20 (which feeds the flame rod) has a sum of 18V. This means that when C17 sums the voltage from the flame sensor, having Flame Ground and Circuit Ground at different voltages creates an offset of +18V. Although the full 120VAC goes to the flame rod, the circuit used to measure the flame voltage has its reference at 18V. This effectively subtracts from the 120VAC Mains so the voltage that goes to the flame rod is effectively reduced to 120 - 18 = 102V.

2. When the 24VAC transformer is out of phase with the 120VAC, the voltage after C20 (which feeds the flame rod) has a sum of 20V. This means that when C17 sums the voltage from the flame sensor, having Flame Ground and Circuit Ground at different voltages creates an offset of 20V. Although the full 120VAC goes to the flame rod, the circuit used to measure the flame voltage has its reference at 20V. This effectively subtracts from the 120VAC Mains so the voltage that goes to the flame rod is effectively reduced to 120 - 20 = 100V. That is not much of a difference.

The next step is to look at the circuit in action.

Although the input impedance of my ‘scope probes is very high (10M) the impedance of the flame circuit is even higher (22M).

To properly measure the circuit I made a very high impedance buffer using a TL062 and powered it from a 12V Gel Cell that I have. For the circuit Click here.

Does the phase of the 24VAC transformer make a difference?

The short answer is No.

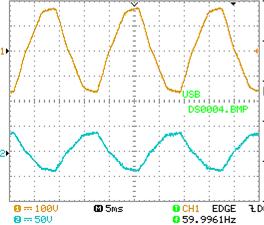

For these tests:

1. The voltage is referenced to Circuit Ground.

2. The top trace is RC7 and the bottom trace is the Flame Voltage at C17.

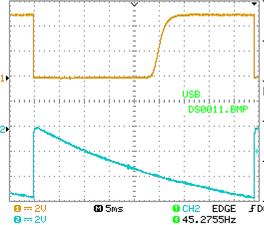

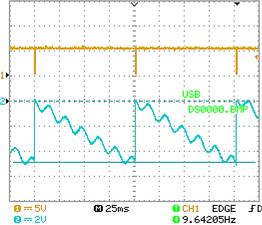

In the following figure the Flame Spoofer is turned on.

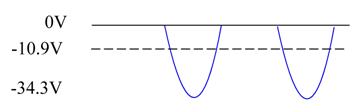

The waves in the bottom trace (the Flame Voltage) are caused by the differences in references discussed above. I will call it the Nurble. The pulsating DC (Figure 35) is being smoothed by C17 and the various resistances in the circuit.

The Flame Voltage ramp goes from 0V to -4.88V.

In this test the Flame Spoofer is turned off so we can get a better look at the Nurble.

The Nurble goes from +0.408V to -0.488V.

Figure 43

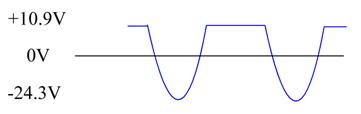

I repeated the test after reversing the phase of the 24VAC transformer.

The Flame Voltage ramp goes from 0V to -4.88V (the same as the first test).

What is different is the Nurble. It goes from +0.384V to -0.720V.

Figure 45

If the Nurbles are different, why is the overall Flame Voltage ramp the same?

What is not shown is that the Flame Voltage ramp jitters. The reason for the jitter is because the Nurbles are not synchronized to the Flame Voltage ramp. In Figure 44 you can see that the first Flame Voltage Ramp starts with a positive half-cycle of the Nurble while the second Flame Voltage ramp starts with a negative half-cycle of the Nurble.

Therefore, although the Nurbles are different the phase of the 24VAC transformer make very little difference and I have ruled out as a cause of my furnace problem the possibility that the 24VAC transformer was connected out of phase when it was installed.

That doesn’t mean that I am ok with the Nurbles caused by using the bridge rectifier (filtered or not).

The Flame Sensor circuit could be made to work about 20% better.

How could this be done?

1. Don’t use a bridge rectifier. Use a half-wave rectifier so that 24VAC_Common and Circuit Ground are the same.

2. Filter the output of the rectifier with an electrolytic capacitor. This will produce 35VDC (with some ripple).

3. Use a voltage regulator to bring the 35VDC down to 24VDC which is what the relays want. A linear regulator would produce some heat. A switching regulator would produce much less heat so I would go with a switching regulator. They are very cheap these days. It would be a small expense that would increase the performance of the flame sensing system.

If you have had (or are having) intractable problems with your gas furnace related to the flame sensor would you have been willing to spend $5 more for your furnace when you bought it so you didn’t (or don‘t) have the problem?

Even if you have never had a problem with your flame sensor would you have been willing to spend the extra $5 to reduce the chance that you would have a problem with your flame sensor?

I would.

I. So, what could it be?

1. At some point while I was investigating the board I noticed that the Inducer Relay (K2) was slow to come on. It would buzz for a while, and then pull in.

While looking for the cause I put a ‘scope probe on RA2 (U1 pin 8). It didn’t buzz when I was holding the probe against the pin. I removed the probe and the buzz came back.

I resoldered the pin, and no buzz.

Then I resoldered all of the U1 pins.

Now the board didn’t work at all.

I resoldered the pins again, this time using more new solder so it wicked down the pins.

It worked!

It is possible one or more of the solder joints on the microcontroller was bad and that when the cold attic was cold enough it caused it to lose contact. (This is less likely to happen with a double sided board.)

Unfortunately I did not think of this until I had already resoldered all of the pins.

A marginal solder joint can be bad because it wasn’t properly soldered when the board was soldered (a “cold solder joint”).

A solder joint can go bad due to thermal cycling. This furnace is in my attic where the temperature can go from the high 30s in Winter to 120 degrees in Summer.

Suppose it is Winter. The attic is 40 degrees. The furnace has not been on for awhile, and the blower compartment (where the control board is located) is 40 degrees. Now the furnace comes on and produces heat. The return air from the house warms the blower compartment to 68 degrees. Then the furnace goes off and the blower compartment returns to 40 degrees. Ok, that’s not so bad.

My air conditioner uses the furnace in the attic. Suppose it is Summer. The attic is 120 degrees. The air conditioner has not been on for awhile and the blower compartment is 120 degrees. Now the air conditioner comes on and the return air from the house cools the blower compartment to 75 degrees. Then the air conditioner goes off and the blower compartment returns to 120 degrees. At the time my furnace problem happened, the furnace (and control board) was 17 years old. That’s 17 years of temperature cycling.

I will note that I have seen a modern furnace where the panels for the blower compartment have a thermal barrier. It was the metalized bubble wrap. You would not want fiberglass insulation inside your furnace because then you would have fiberglass particles in the air being delivered to the house. :-( (My furnaces do not have a thermal barrier on the panels.)

Another thing about temperatures.

The Control Board is mounted in a plastic box with a metal cover.

As a result the heat produced by the Control Board will tend to get trapped in the box and keep the Control Board warm in cold temperatures. And since it is located in the Blower Compartment it will also be warmed by the return air coming from the house (Winter) or cooled by the return air when the air conditioner is running (Summer).

During Cavallero’s first visit when Mike noticed that the Flame Good LED took a long time to turn on, I noticed that the metal cover was not on the Control Board box. It was on the floor of the platform. I hadn’t removed it so the most likely reason for it being off is that the Guy from Company A had removed it so he could see the LEDs on the Control Board and hadn’t put it back. This would have made the Control Board much colder than it otherwise would have been. (One night when it was about 15 degrees outside and in the 30’s in the attic I determined that the furnace was running about 50% of the time.) That gave the Control Board time to get really cold. If the Guy from Company A had put the cover plate back I might not have had a problem with the furnace.

2. There is another potential problem. This is with the age of the Control Board and the high temperatures in my attic in Summer.

The PIC16C57 microcontroller stores its program in EPROM. The EPROM (Electrically Programmable Read Only Memory) has a long history. I wrote about it several years ago. (Click here)

An EPROM stores the data bits as charges in a floating gate isolated by two oxide layers. Some EPROMs come with a quartz window which allows the memory to be erased by ultraviolet light. Don’t laugh. This was a big improvement over what had been available before EPROMs, which were Masked ROMs. With Masked ROMs the bits are determined by the masks used in making the ROM and cannot be changed after the part is made. Since it requires making semiconductor masks it could take weeks to months to get them made.

EPROMs cost more than masked ROMs but had the advantage that they could be programmed in-house by your own programming equipment and could be erased if necessary. The idea was that EPROMs would be used during the development of a product and to make prototypes, then masked ROMs would be used for production.

What if, after you send out the order for Masked ROMs or when you get the Masked ROMs back, you discover a bug in your software? Getting new ones made required more time and more money because making Masked ROMs required a substantial one-time charge (NRE = Non-Recurring Engineering charge) to make the masks. Oops.

As the cost of EPROMs started coming down some companies used them in the production product. Atari Coin-Op was one of them. (Atari Consumer continued to use Masked ROMs for the 2600 game console and was, at one time, the largest user of Masked ROMs in the world.)

At some point the EPROM manufacturers did a study and found out that most EPROMs were programmed only once. The quartz window was a large cost factor because it requires a ceramic package so they came out with EPROMs without the window in a cheaper plastic package. That meant that they could not be erased so they were called One-Time Programmable (OTP) EPROMs.

Here is one with the window.

Here is an OTP. No window.

When they came out with single-chip microprocessors that had everything on the chip (called microcontrollers) they generally used either EPROMs or Masked ROMs on the chip for program memory. They had two versions of EPROMs. One had a window so you could erase it (use it for development) and the other had no window (OTP) for production.

The PIC16C57-RCI/P used in my Ruud Control Board uses an OTP EPROM.

Here is what is important.

The bits are stored as charges in a floating gate isolated by two oxide layers. No oxide layer is a perfect insulator. Eventually the charges will leak away, and there goes your program/data. The technical term is “Bit Rot.” (And since programming the memory causes some stress to the part it can only undergo a limited number of write cycles. Then it wears out. It’s called “Wear Out.”)

How long does it take for Bit Rot to set in?

It depends on the operating voltage of the part and its temperature history. The higher the voltage and the higher the temperature history of the part the sooner it starts to happen. EPROM manufacturers used to discuss this problem and provide data and charts. They stopped providing this information decades ago. I remember that 20 years was reasonable for the 27C512s which I used in several of the Atari Coin-Op games that I designed the hardware for. I am going here on my own memory (which is also subject to Bit Rot).

Since my furnace was manufactured in 1995, in 2012 it was about 17 years old. And the PIC16C57 was also about 17 years old. And it had lived some of its life at temperatures around 120 degrees.

Had Bit Rot set in, in my PIC16C57? Is that why it stopped working properly? Is that why the Diagnostic LED never flashes an Error Code?

Probably not. If Bit Rot had set in then it is likely that the program would have totally crashed.

Still, it was probably a good idea to replace the Control Board.

My other furnace is in the garage so its temperature history is much lower. How old is your furnace and where is it?

If you have gotten this far there is something else you should know.

You know those Flash Memory Cards and USB Memory sticks that are everywhere nowadays and you may have noticed the increasing use of Solid State Drives (SSDs) ?

The underlying technology in these memories is:

{Drum Roll}

EPROM Technology!

The bits are stored as charges in a floating gate isolated by two oxide layers.

The difference are:

1. The memories are electrically erasable, and they are erasable in small blocks. You don’t erase the entire memory in order to write one new byte.

2. The memories contain a controller to spread the memory write cycles out over the entire memory so you are not always writing to the same blocks. It’s called “Load Leveling.” If the capacity of your flash memory is going down it means that blocks are wearing out and being mapped out of use.

What this means is that you should not use Flash Memory Cards, USB Memory Drives, and SSDs to archive data.

Eventually they will all suffer from Bit Rot.

What media should you use to archive data?

1. For cost and storage capacity it is hard to beat Hard Disk Drives. However, HDDs are mechanical and don’t last forever. What happens, though, is that HDDs get filled up and people copy them to new and bigger HDDs. When you do that be sure to copy all of the files that you want to keep. My first HDD was 60 Mbytes, cost several hundred dollars, and came with its own disk controller card. (It was before the IDE interface was invented.) My standard HDD now is 1 Terabyte and costs around $50. A Terabyte is 1000 Gigabytes and a Gigabyte is 1,000 Megabytes so a Terabyte is 1 million Megabytes.

The other problem with HDDs is that they can be wiped out by an Electromagnetic Pulse (EMP). EMPs are produced by nuclear devices, even small ones. A small nuclear device exploded 100 miles above Kansas would bring down the Eastern Grid, the Western Grid, and the Texas Grid. The transformers in these 750 KV lines are already operating at or slightly above their rated capacity. The added current induced by an EMP would burn them out. The transformers are not stock items and are only built to order. You might think we would have had a bunch of them built ahead of time and stored them in a warehouse (or warehouses) but Congress says, “No, we can’t afford it.” http://securethegrid.com/the-basics-of-grid-security/

If your HDD is anywhere near an EMP it will be destroyed unless it is in a Faraday Cage (https://en.wikipedia.org/wiki/Faraday_cage) or deep enough underground.

EMPs are also produced by a solar event called a Coronal Mass Ejection (CME). https://en.wikipedia.org/wiki/Coronal_mass_ejection

A CME hit the Earth in 1859 and burned out telegraph lines all over North America. The reason it didn’t burn out anything else is because there wasn’t anything else. No power lines, no telephone lines, no phonographs, no radios, no televisions, no computers, no cell phones, no ipods. Nothing. (The event of 1859 is known as the Carrington Event https://en.wikipedia.org/wiki/Solar_storm_of_1859)

Unfortunately, a very large CME will also blow away our atmosphere. {Gasp!}

2. Optical discs like CDs and DVDs should survive an EMP. Unfortunately the storage capacity of optical discs has not kept pace with HDDs. A CD is good for only 650 MBytes. A standard DVD is 4.3 GBytes. A Blu-Ray DVD is 25 GBytes (50 GBytes for dual layer). At 50 GBytes per disc it would take 20 Blu-Ray discs to equal a 1 Terabyte HDD.

Sony and Panasonic have announced a new optical disc system that can store 1.5 Terabytes per disc and will keep the data for 50 years. http://panasonic.net/avc/archiver

I hope they are successful and it becomes cheap enough for consumers to buy.

3. For long term storage you cannot beat the old technology.

a. Engraving symbols in stone. It is low bandwidth and low storage density but storage lifetime can be several thousand years.

b. Writing ink on animal skins (like sheepskins). Also low bandwidth and low density. Storage lifetime can be a thousand years if properly stored.

c. Printing on pulp paper. Better bandwidth and density than stone and animal skins. Can be machine written (a computer printer). The storage lifetime can be several hundred years (maybe more) if properly stored but only if high quality (acid-free) paper is used.

Suppose all of our stored data were wiped out (and us, too).

Ten thousand years from now when alien archeologists are visiting our planet the only record of our civilization will be what they find in our landfills.

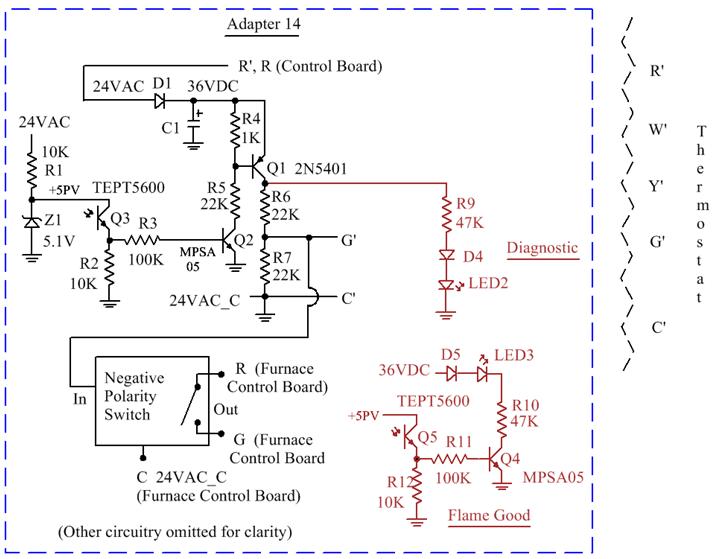

J. I invent a better flame sensing system

I invented a better flame sensing system, reduced it to practice by building it, and filed a patent application.

|

ABSTRACT OF THE DISCLOSURE This invention relates to the field of sensing flames in equipment such as gas furnaces by using the electrical properties of flames. In a first group of embodiments flame rectification is used to cause distortion of a signal having a selected waveform. A harmonic of the distorted waveform is detected thereby providing flame proof. In a second group of embodiments flame rectification is used as a mixer to cause two signals having selected waveforms to produce sum and difference signals. The sum and/or difference signals are detected thereby providing flame proof.

|

For the published patent application click here.

Assuming I get the patent will the World:

1. Beat a path to my door?

2. Beat me up and steal it?

3. Ignore me?

I’ll let you know.

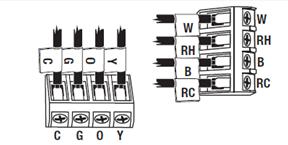

K. About Thermostats

The Summer after my furnace was fixed I wanted to use my air conditioner. It started up and then promptly shut down. This time the problem seemed to be the thermostat and occurred when the set point for cooling was more than 2 degrees below the room temperature.

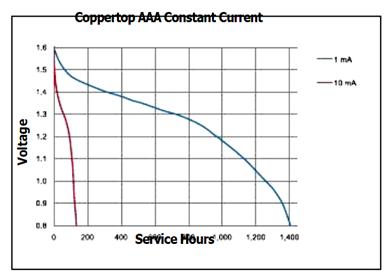

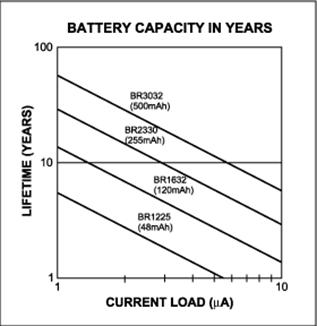

My old thermostat was a Lux 9000. It operates solely on its batteries because it does not use the 24VAC from the furnace. It can’t. There is no “C” terminal. (The “C” terminal is 24VAC_Common.) On the other hand the drain on the battery is extremely small, about 6.5 uA. I liked the Lux 9000 because it explicitly told you how long the blower had been running. This made it easy to determine when to change the filters. I wish they still made the Lux 9000, but with a “C” Terminal.

When I put in a new thermostat I learned something interesting about thermostats.

Some history.

Before there were electronic thermostats the thermostats were mechanical devices that used a bimetallic strip made of two dissimilar metals that expand and contract as different rates as the temperature changes.. An early patent that teaches the use of a bimetallic strip is U.S. Patent No. 281,884 Electric Tele-Thermoscope issued July 24, 1883 to Warren S. Johnson. The two dissimilar metal strips are wound together in a spiral with the inside end fixed and the outside end controlling a beam lever. Under each contact point of the beam lever is a small cup of mercury. When the temperature is below the set point one end of the beam contacts its pool of mercury and the contact on the other end of the beam is lifted out of its mercury pool. When the temperature is above the set point the beam lever pivots reversing which pool of mercury is in contact with its respective beam lever contact. For the Johnson patent click here. (I cleaned up the USPTO’s patent by straightening the pages and removing their scanning artifacts.) Warren S. Johnson was the Johnson in Johnson Controls (http://www.johnsoncontrols.com/content/us/en/about/our_history/warren_s__johnson.html)

This evolved so that instead of two open cups of mercury the mercury was in a sealed capsule with two electrodes. As before, the bimetallic strip is wound in a spiral with the inside fixed. However, instead of the open cups of mercury a mercury capsule is mounted at the free end of the spiral. The expansion and contraction of the bimetallic strip around the set point causes the mercury capsule to tilt one way or the other. One way causes the mercury to wet the electrodes and complete the circuit. The other way draws the mercury away from the electrodes opening the circuit. The mercury capsule is elongated to produce hysteresis. An example of a mercury switch thermostat is U.S. Patent 1,822,605 Mercury switch thermostat issued September 8, 1931 to Teeple. Click here. It should be appreciated that thermostats with mercury must be installed perfectly level or the set point will be wrong.

In other mechanical bimetallic strip thermostats the bimetallic strips directly make (or do not make) electrical contact with each other. Hysteresis is provided by a magnet. An example is U.S. Patent 2,129,477 Adjustable metallic thermostat issued September 6, 1938 to Parks. Click here.

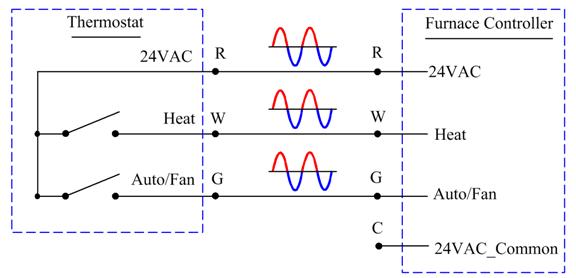

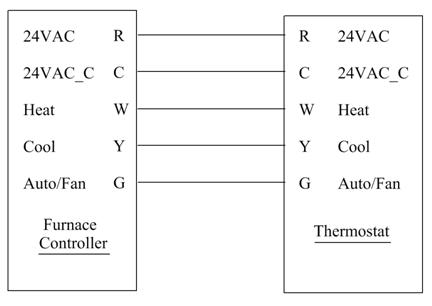

These mechanical thermostats require only two wires to turn the furnace on.

|

If you are replacing an old thermostat that has the mercury capsule you need to dispose of it properly. Don’t put it out in the trash. There is a Web site that will tell you where you can bring your old thermostat: www.thermostat-recycle.org

If you have an original Johnson thermostat that still has mercury in the open cups then you should call either the hazmat team or Antiques Roadshow.

|

There was a famous and ubiquitous (and round) mechanical thermostat made by Honeywell. There are probably millions of them still in use. It looks like this one.

Figure 46

But this one, a Honeywell CT87K, is totally electronic and contains a Lithium coin cell. For the manual click here.

It currently costs $29.68 at Home Depot. That’s a lot to pay for a Retro (but electronic) thermostat. I will examine it in some detail later on.

Mechanical thermostats work by closing two contacts. That’s it.

When the contacts close they tell the furnace to run.

Older furnace controllers used relay logic to control the furnace so the thermostat contacts completed a circuit that turned on a relay that started the process.

Furnace logic is very simple and can be accomplished by a few relays, maybe some with a delay built-in. From https://en.wikipedia.org/wiki/Relay

Timing relays are arranged for an intentional delay in operating their contacts. A very short (a fraction of a second) delay would use a copper disk between the armature and moving blade assembly. Current flowing in the disk maintains magnetic field for a short time, lengthening release time. For a slightly longer (up to a minute) delay, a dashpot is used. A dashpot is a piston filled with fluid that is allowed to escape slowly; both air-filled and oil-filled dashpots are used. The time period can be varied by increasing or decreasing the flow rate.

Not long ago relay logic was used to control elevators. And a long time ago (but within my lifetime) the phone system was run by relays and relay logic.

Back to furnaces.

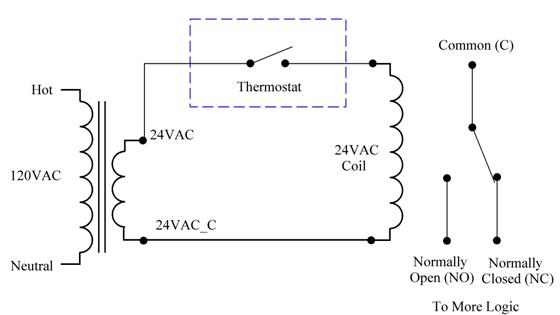

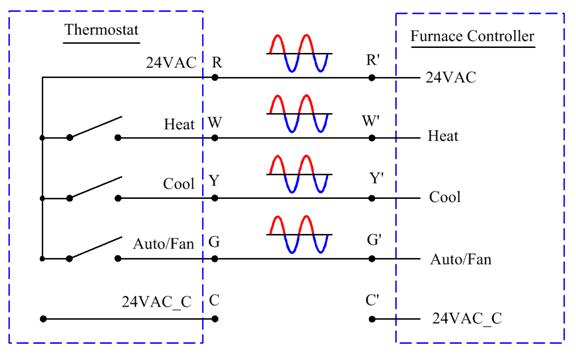

A mechanical thermostat only needs two wires to control the furnace. The transformer is in the furnace and the relay is in the furnace controller.

Figure 47

If you want to be able to turn just the fan on, it takes only one more wire. The fan switch uses the 24VAC wire that already goes to the thermostat and it turns on its own relay.

If you have central air conditioning that’s one more wire.

Since mechanical thermostats didn’t use any power themselves there was no reason to run a wire for 24VAC_Common, so installers didn’t.

Then thermostats went electronic.

Nowadays, although there are still mechanical thermostats most thermostats are electronic and need power to operate. An example of an early patent for an electronic thermostat is U.S. Patent 3,942,718 Electronic thermostat issued March 9, 1976 to Palmieri. Click here. This patent does not show where it gets its power from but since it uses discrete logic it is unlikely that the power came from batteries. When the patent application was filed in 1973 there were no microcontrollers, and microprocessors required considerable support circuitry, all of which required more power than was practical to get from batteries for long term use. Therefore, this thermostat would have required external power.

An example of an early patent for a User programmable thermostat is U.S. Patent 4,442,972 Electrically controlled programmable digital thermostat and method for regulating the operation of multistage heating and cooling systems issued April 17, 1984 Sahay, et al. Click here. This patent also required external power. See Figure 5 element 35. It is the furnace transformer.

Since thermostats using the technology taught by both ‘718 and ‘972 would have required external power (such as furnace power) the sales of these thermostats would have generally been limited to new construction and to homeowners willing to install (or have installed) a new cable from the furnace to the thermostat.

Nowadays with the availability of very low power microcontrollers a thermostat may operate solely from its batteries. Some thermostats are designed so that the batteries may last for several years before they need to be replaced. Some thermostats may need its batteries replaced in as little as a year. If the batteries die the furnace will not work and the home’s residents may wake up in the morning to a very cold house. If the residents are away at the time the failure of the furnace to operate may result in frozen and burst water pipes.

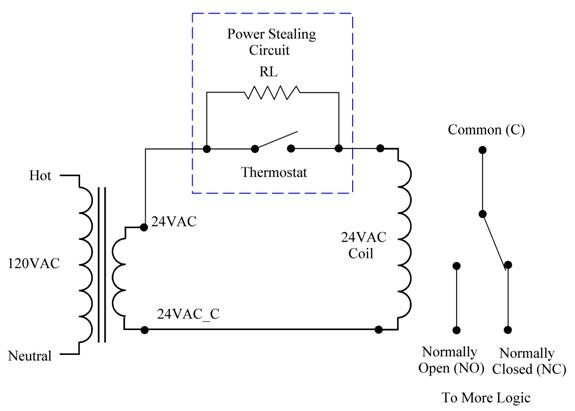

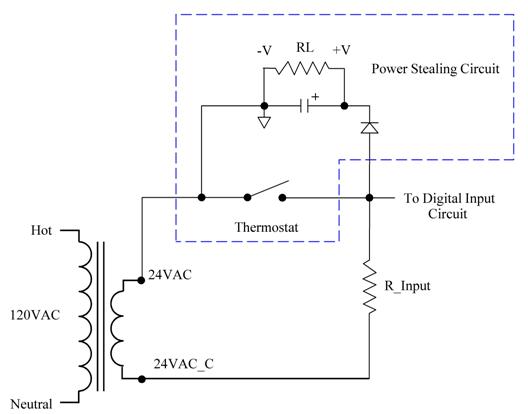

Some thermostats augment battery power by the process known as Power Stealing. In Power Stealing the thermostat operates on a small leakage current through the furnace controller input.

Here is how it works.

A relay requires a minimum amount of current to pull-in. Below that current it will not pull-in. So you can use a resistor (or a transformer) across the thermostat switch to allow a current to flow through the relay that will not pull-in the relay. Then you use the voltage developed across the resistor (or transformer) to either charge a large capacitor or recharge a battery.

Figure 48

You will probably want to run your thermostat circuitry from DC.

Figure 49

The caveats are:

a. The current you steal cannot be large enough to pull in the relay.

b. Relays also have a drop-out current which is less than the pull-in current. Once a relay has pulled in, it takes less current to keep it pulled in, so the current you can steal has to be less than the drop-out current.

c. Once the thermostat has closed its contacts (a Call For Heat) there is no power available to be stolen. Therefore you need a battery or very large capacitor to operate the thermostat for as long as the furnace is running. How long is that? Ten minutes? An hour? Four hours?

An early patent that teaches Power Stealing is U.S. Patent 4,211,362 Smoke detecting timer controlled thermostat issued July 8, 1980 to Johnson. Click here.

Claim 2:

2. A thermostat as described in claim 1 wherein said thermostat is powered by a small leakage current-flow from said power source through said heat exchanger device during off states of said heat exchanger device, said thermostat including a battery means for supplying operating power to said thermostat when full power is allowed to flow to said heat exchanger device, said thermostat including a power supply circuit means for limiting the current and regulating the voltage upon which said thermostat operates.

Look at Figure 1. This was an analog thermostat except for the digital display.

You should also see U.S. Patent 4,193,006 Multi-stage controller issued March 11, 1980 to Kabat, et al. Click here. Figure 2 shows a digital thermostat that uses discrete logic. No microcontroller. Not even a computer.

Unless you have a really old furnace controller it probably won’t use relay logic. The inputs will be digital. The digital inputs will be relatively high impedance. If you design furnace controllers and you want them to work with power-stealing thermostats you have to provide an input resistor.

If you design furnace controllers what size R_Input resistor should you use, and if you design thermostats what size R_Input resistor should you assume is being used?

Bear in mind that when the thermostat closes you will have the full 24VAC across your resistor and

Power = V2 / R

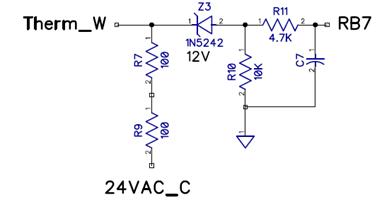

The Rudd Furnace Controller uses two 100 Ohm, 5 Watt Resistors.

Figure 50

Power = V2 / R = 24*24/200 = 2.88 Watts

Each Resistor is a 5 Watt resistor, which gives plenty of margin for heat dissipation.

Other boards don’t use 200 Ohms. I have seen several boards (newer than this one) that use 1K on all the inputs.

If the thermostat has a separate switch for controlling the Fan (Blower) you can steal its power, too. The Fan switch will have two positions: Auto and Manual.

In the Auto position the furnace controller controls the blower. In the Manual position the Blower runs continuously. What if you have the Fan switch on Manual? If the thermostat is smart it will know that when it issues a Call For Heat the furnace controller will control the blower so it doesn’t have to, so it can steal power from the Fan circuit.

If the thermostat also controls an air conditioner it is a good bet that the furnace and the air conditioner won’t both be on at the same time. You can always steal power from one or the other.

If the thermostat can get enough stolen power then the only time you need battery power is when the furnace power is off (like during a power failure). Even then the battery is needed only to keep the clock running and remember the settings. And if the microcontroller has some non-volatile memory it can write to, then the battery is only needed to run the clock.

But what if you have stolen power from all of the available sources (Heat, Fan, and Cool) and it is still not enough to run the thermostat? Then you will be using battery power.

And even if the thermostat uses rechargeable batteries (and it probably doesn’t) batteries have a finite lifetime. Rechargeable batteries can only be recharged a limited number of times. And all batteries have a self-discharge rate. Eventually they will die even if they are not being used.

I will now theorize that:

a. Once the manufacturers produced electronic thermostats that work by Power Stealing they saw no reason to design them to also run on the 24VAC from the furnace.

b. Then, when low power circuitry became available there was less reason to run on 24VAC from the furnace or to use Power Stealing. Just run them on the batteries.

Many of today’s thermostats run solely on the batteries.

For example:

a. My old Lux 9000 runs solely on the batteries. However, the unit uses two AA batteries and draws only 6.5 uA. That would allow the batteries to last for several years.

b. The Honeywell RTH221B is an electronic 7-day programmable thermostat that also does cooling. (The RTH2300 version has a backlight.) Click here. It uses two AAA batteries. It does not use Power Stealing. And there is no “C” terminal.

Figure 51

I tested one. The nominal battery drain is 40 uA.

While that is much more than the Lux 9000 it is still very small. The Honeywell unit uses a Texas Instruments M430F413 microcontroller. I suspect that the Lux 9000 uses a custom integrated circuit designed using the techniques used in making digital watches. (If the Lux 9000 was installed when my house was built, then it was made sometime in or before 1995.)

I tested it in my test fixture. The battery drain does not change when the control board being tested has power. Therefore the thermostat does not use Power Stealing.

There is something curious about the Honeywell RTH221B.

Figure 52

There is a label next to a terminal on the PC board that says “C”. That is the terminal in the drawing that says “not used.” When I tested it in my test fixture the battery current did not change. Therefore, it doesn’t go anywhere on the PC Board. (Boooh.)

The relatively high current drain, the lack of Power Stealing, and the lack of a “C” Terminal explains why Honeywell says to replace the batteries once a year.

But the Honeywell RTH221B is only $19.88 at Home Depot.

Let’s look at the Honeywell CT87K. This is the Retro Round Dial thermostat that used to be totally mechanical but is now electronic. But it is still round.

Figure 53

Here is the circuit board.

Figure 54 - CT87K Top

Figure 55 - CT87K Bottom

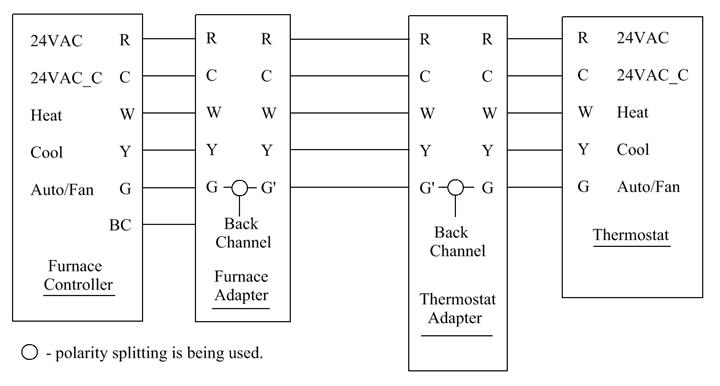

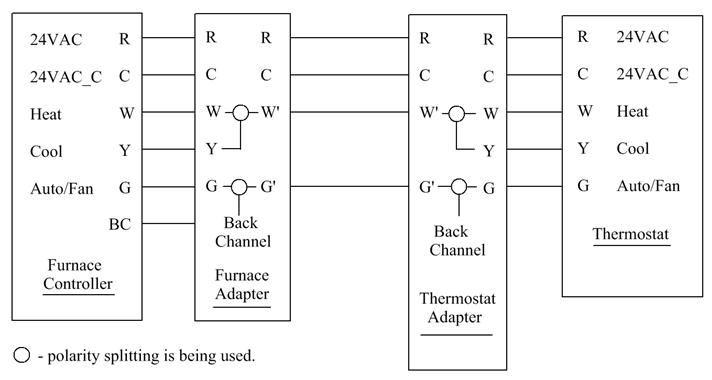

It cannot run on furnace power but it does do Power Stealing (about 0.7mA when there is no Call For Heat). The Power Stealing uses only the negative half-cycles. That makes sense. By now all of the furnace control boards are solid state and the inputs use only the positive half-cycles. Using only the negative half-cycles for Power Stealing makes it unlikely that the furnace control board will interpret it as a valid input. This has ramifications for the use of Polarity Splitting to be discussed later.

It has a CR2450 Lithium coin cell which is 3V and has an amazing 620mAhr capacity. That compares favorably to two AAA alkaline batteries which are rated for 1,000mAhrs.

The microcontroller is an Atmel Mega 48PA AU 1339. (The “1339” might be a lot number or a date code.)

This is an interesting device.

The Power Consumption at 1MHz, 1.8V, 25°C:

Active Mode: 0.2mA

Power-down Mode: 0.1μA

Power-save Mode: 0.75μA (Including 32kHz RTC)

The active mode (0.2mA = 200uA) looks large but it is likely that it has been programmed to spend most of its time sleeping and only wakes up periodically, maybe for 1ms every second. (One ms is an eternity for both microcontrollers and androids.)

The Power-save Mode is amazing. Just 0.75uA.

Earlier I complained that no one tells you about the retention time for their EPROMs and EPROM-based devices anymore.

Well, Atmel does.

This is from the Datasheet Summary:

High Endurance Non-volatile Memory Segments

4/8/16/32KBytes of In-System Self-Programmable Flash program memory

256/512/512/1KBytes EEPROM

512/1K/1K/2KBytes Internal SRAM

Write/Erase Cycles: 10,000 Flash/100,000 EEPROM

Data retention: 20 years at 85°C/100 years at 25°C(1)

Let me repeat the last part. Data retention is expected to be 20 years at 85°C (185°F) or 100 years at 25°C (77°F). These are very impressive numbers, and I expect that my thermostat will spend more of its lifetime at 77°F than it will at 185°F. (Note that Atmel’s numbers are projected numbers that would be based on the established practice of doing some testing and some calculations.)

For Atmel’s Datasheet Summary click here.

The board has a 1,000 uF electrolytic and a device marked “473 ▌5.5V E7”. It doesn’t have a manufacturer’s name on it unless “ ▌” is a symbol. I believe it is a 47,000uF supercapacitor.

Figure 56

This is a 10,000uF Supercapacitor made by Kemet.

http://www.kemet.com/Lists/ProductCatalog/Attachments/408/KEM_S6011_FC.pdf

Figure 57

Supercapacitors are generally used to provide backup power to a low current device. This would help the microcontroller ride out the time during a Call For Heat when there is no Power Stealing.

The next part to consider is the relay that is used to provide the closed contacts to run the furnace. The relay is an Omron G6SK-2F-H.

Figure 58

This is a latching relay. This latching relay has two coils. You provide a pulse to one coil and it turns the relay on, and it stays on (latched) until you provide a pulse to the other coil which turns it off. When used to control a furnace you have to make sure the controller doesn’t crash with the relay latched. I think Honeywell has done that with the low power Atmel microcontroller, the Lithium coin cell, and the supercapacitor.

The Honeywell CT87K is basically a 2-wire thermostat. There is no Off switch. There is no Fan Switch (Auto/On). Some people like to run the Fan (Blower) to circulate the air when the furnace is not on. Well, not with this one.

There is a third terminal labeled “Y”.

Figure 59

The “Y” terminal usually means “Call For Cooling.” Not here. Here it is for a hot water heat-only system. (You probably wouldn’t put a heat-only thermostat on a system that has an air conditioner anyway.)

There was probably an engineering design decision that Honeywell made. In Fan Auto mode the furnace controller controls the fan and the Fan Input is not used. Since there is no Fan switch they could have used the Fan Input for Power Stealing so there would be Power Stealing all the time, or at least whenever the furnace has power. (When the furnace doesn’t have power it doesn’t matter if the thermostat is working.) In a strictly 2-wire system there would not be a wire for the Fan switch so they would have needed to design the thermostat exactly the way they did anyway, with a low power microcontroller, a supercapacitor, and a latching relay.

The CT87K has option switches for setting the Cycle Rate.

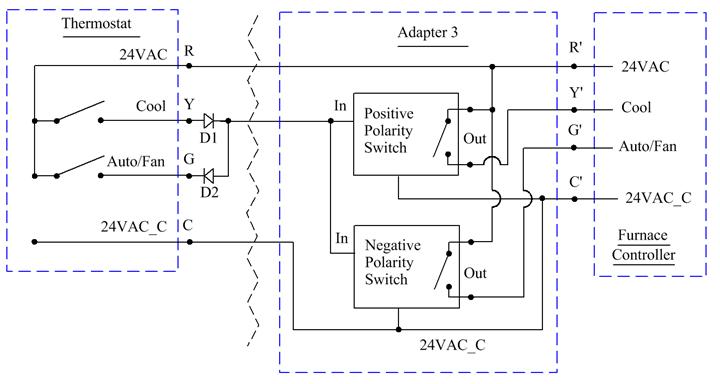

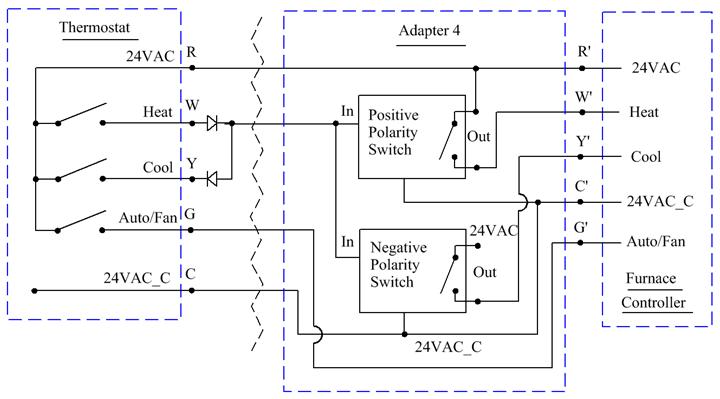

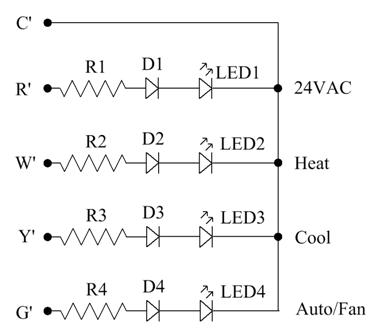

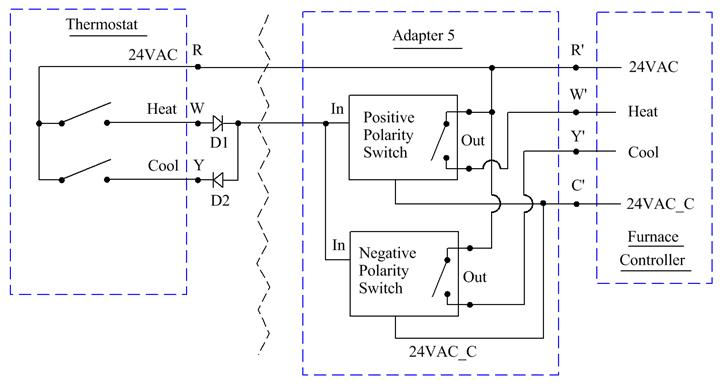

Figure 60

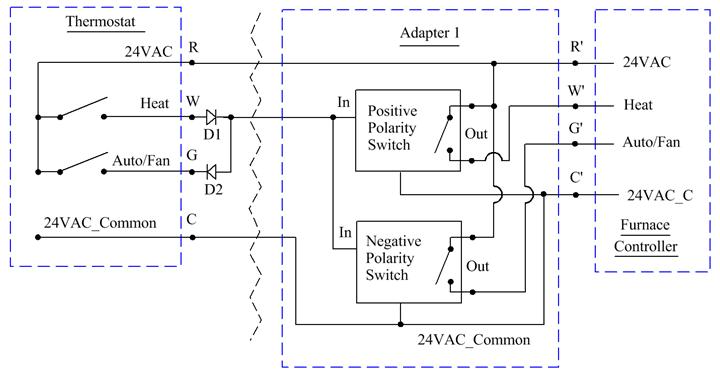

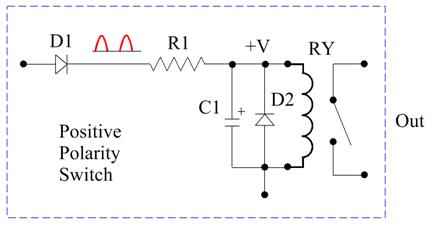

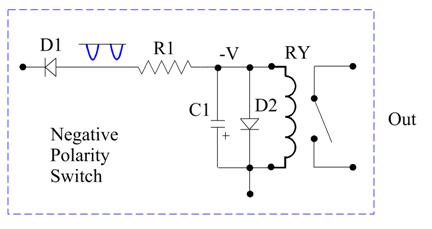

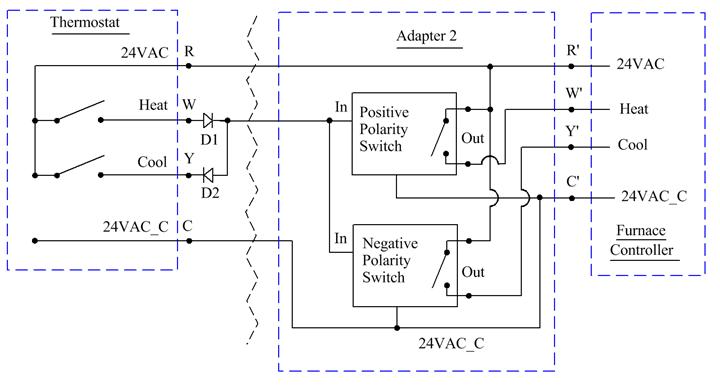

The Cycle Rate is really the Temperature Swing, which is the temperature hysteresis. A small temperature swing (like 0.25°F) means that the furnace will cycle on and off frequently but your house will maintain a temperature within narrow limits. A large temperature swing (like 2°F) means your furnace will cycle less frequently but the temperature in your house will also vary by 2°F. It would be nice if Honeywell came out and said this, and said what the temperature swing is for the different options. This also goes for all the other thermostat manufacturers who do not make this matter clear.